The smart factory represents a leap forward from more traditional automation to a fully connected and flexible system—one that can use a constant stream of data from connected operations and production systems to learn and adapt to new demands. A true smart factory can integrate data from system-wide physical, operational, and human assets to drive manufacturing, maintenance, inventory tracking, digitization of operations through the digital twin, and other types of activities across the entire manufacturing network. The result can be a more efficient and agile system, less production downtime, and a greater ability to predict and adjust to changes in the facility or broader network, possibly leading to better positioning in the competitive marketplace.

As a Manufacturer, your production lines or machines are one of your most valuable assets. Each machine in your production line needs to have a high performance, should be flexible to use and easy to control. The machines or production lines needs to be reliable, available, maintainable and most important safe for your workers.

The solution Machine Automation & Control will help you to upgrade outdated production lines in the factory or develop new equipment and machines for the Original Equipment Manufacturers. The latest software-based technology and IIoT devices will be provided to achieve this goal.

With the solution Machine Automation & Control , your assets will be IIoT-Ready and able to provide data that will support maintenance, quality and production. Besides that, your assets will be Smart Factory-Ready for future centralized Factory Monitoring & Control supported by platforms like Supervisory Control & Data Acquisition (SCADA) or (Manufacturing Execution System (MES/MOMS).

Our solutions and provides :

- Upgrade outdated production lines or machines to Smart Factory- or IIoT-Ready

- Develop and implement Automation & Control for new machines

- Maintenance, Repair and Overhaul (MRO) of outdated production lines or machines

As a Manufacturer, you can see that the competition is growing every day. You need to secure your position by improving the operational efficiency, shorten the time-to-market and optimize the cost.

Before you know HOW to improve you need to understand:

WHAT are the Production Losses?

WHAT are the causes of Production Losses in manufacturing?

The Production Performance Manager will provide real-time production performance monitoring based on OEE & ANDON principles. The day-to-day production performance will help your company improve continuously. You gather and present information quick and easy. With this real-time information, your organization will benefit and is able to improve 360 degrees.

Our solutions and provides :

Collect : Extract & store the relevant production data

Visualize : Real-time shop floor information for direct troubleshooting

Analyse : Provides tools & report dashboards for direct insight

Improve : Production, maintenance & quality can act based on facts & figures

As a Manufacturer, you know that machines’ minimal cycle-time and produce high quality are vital aspect to meet high volume productions with zero defect. With special designed mechanical structure and computerized controls, robots are able to improve your productions’ quality and quantity. Industrial robots have advantages in the following 4 areas :

- Accuracy & precision

- Efficiency & speed

- Ability to work in environment unsafe for human

- Free from human limitations

Our Industrial robots ranging from Articulated (6-axis), SCARA (4-axis) and Cartesian (3-axis) robot with the various reach length, payload and with repeatability as low as ±0.005mm, we have the solution to help improve your production quality and quantity.

Industrial robots are usually coupled with the following options for specific applications :

- Force sensor – For control, detection and logging on force-sensitive applications

- 2D Vision systems – For guidance to robot without using mechanical locating tools/jigs

- 3D Vision – Capable of bin picking (picking up workpieces loaded in bulk) without the need to register difficult workpiece shapes

- Electric hand/gripper – Higher flexibility and accuracy on gripping of workpiece.

As a Manufacturer, you want to keep overhead costs low and maintain high production efficiency to maximize operating performance & overall profitability. Plus, having the difficulties to retain skilled workers, and training new workers requires long duration, our CoBot solution is the right automation solution for your business.

Collaborative robots or CoBots are designed to work near or hand-in-hand with humans without the need of safety cage/barrier which has very high flexibility and scalability with the high degree of freedom design. They are required to comply with ISO 13849-1 (Safety of Machinery).

Suitable for assisting human in task and operate in areas with low proximity to operators.

As a Manufacturer, you have challenges to retain skilled workers. Training of production staff requires time and expenses and the labour cost is increasing in most countries around the world.

The human cognitive limitations can be a critical factor in the processing of data. This can lead to economic & quality losses, safety risks and operational inefficiency of the production process. On the other hand, you see that the number of connected devices, volumes of data and the complexity of the automation in the production process is growing every day.

Your production staff needs to process a larger amount of data in a shorter timeline.

At this moment 100% decision-making without human intervention is for most of the manufacturers still a concept. It is important to support and facilitate your production staff and present the data as small chunks of real-time information and in the right context. The parts of the process where the safety risk is high and the ‘processing speed’ of human can have a negative impact on the environment and operational efficiency it is highly recommended to let automation take control.

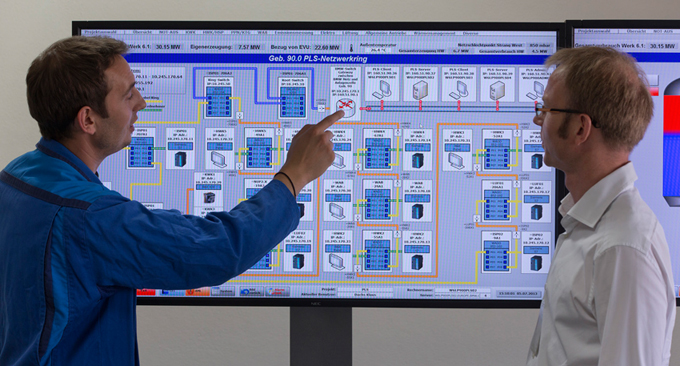

Process Monitoring & Control is able to Collect the data from the production line, to Visualize the real-time information from factory floor till management board and to Control the process automatically or manual. You will be able to Analyse the relevant data and to accelerate in decision-making based on facts & figures to Improve your efficiency. The solution Factory Monitoring & Control is also known as Supervisory Control & Data Acquisition SCADA or (Hybrid) Distributed Control System (DCS).

The solution of Process Monitoring & Control provides :

- Collection and central storage of production data

- Processing and monitoring of real-time information

- Remote and centralized control of the production process

- Open interface with third party systems & Enterprise Level

- Open interface with different communication network protocols

- Reports, Dashboard & Analysing tools.

Copyright © 2018 Landarch Innovation Co.,ltd. All rights reserved.